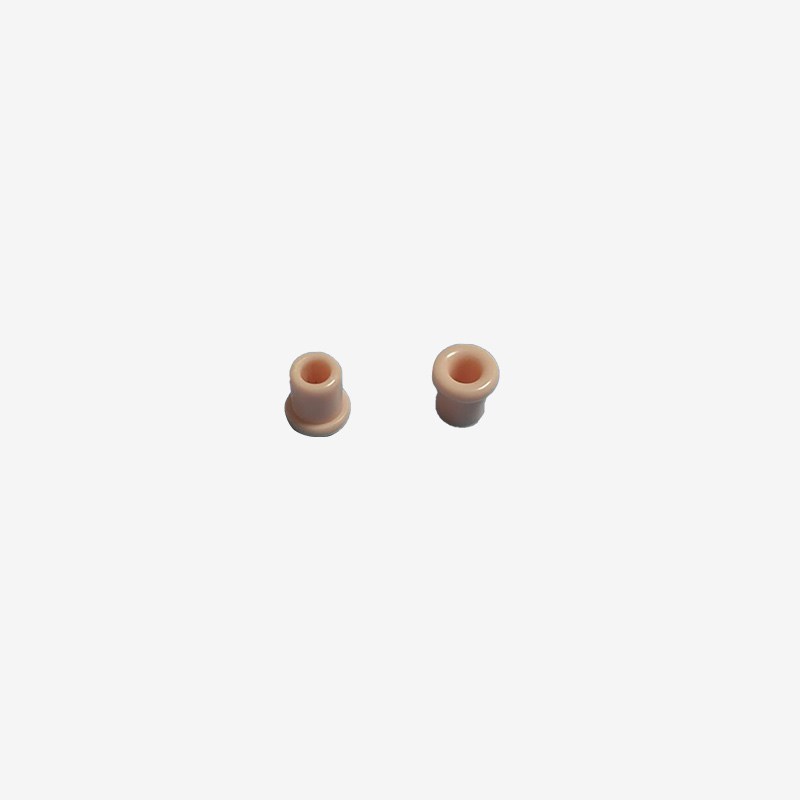

Alumina Ceramic Part of Textile Machinery

Application Field

Textile ceramics parts which are widely using in textile machinery with high mechanical property、high hardness、long wearing、 large insulation resistance、good corrosion preventive 、high temperature resistant.

Textile ceramics parts have a wide range of applications in daily life. We say almunia ceramics parts can be used in processes such as yarn interlacing, drawing, spinning, plasticization, weaving, and knitting and so on. China is biggest market of textile ceramics parts. In addition ,the competitive domestic textile ceramic accessories industry is also constantly changing.

Some domestic enterprises have gradually narrowed the gap with foreign brands through technological research and development and quality improvement, and their market share has gradually increased. At the same time, some foreign brands have gradually entered the Chinese market, further promoting the textile ceramic accessories industry.

Details

Quantity requirement: 1pc to 1 million pcs. There is no MQQ limited.

Sample lead time: tooling making is 15days+ sample making 15days.

Production lead time: 15 to 45days.

Payment term: negotiated by both parties.

Production process:

Alumina(AL2O3) ceramic is an industrial ceramic which has high hardness, long wearing, and can only be formed by diamond grinding. It is manufactured from bauxite and completed by injection molding, pressing, sintering, grinding, sintering and machining process.

Physical & Chemical Data

| Alumina Ceramic(AL2O3) Character Referance Sheet | |||||

| Decription | unit | Grade A95% | Grade A97% | Grade A99% | Grade A99.7% |

| Density | g/cm3 | 3.6 | 3.72 | 3.85 | 3.85 |

| Flexural | Mpa | 290 | 300 | 350 | 350 |

| Compressive strength | Mpa | 3300 | 3400 | 3600 | 3600 |

| Modulus of elasticity | Gpa | 340 | 350 | 380 | 380 |

| Impact resistance | Mpm1/2 | 3.9 | 4 | 5 | 5 |

| Weibull modulus | M | 10 | 10 | 11 | 11 |

| Vickers hardulus | Hv0.5 | 1800 | 1850 | 1900 | 1900 |

| Thermal Expansion coefficient | 10-6k-1 | 5.0-8.3 | 5.0-8.3 | 5.4-8.3 | 5.4-8.3 |

| Thermal conductivity | W/Mk | 23 | 24 | 27 | 27 |

| Thermal shock Resistance | △T℃ | 250 | 250 | 270 | 270 |

| Max use temperature | ℃ | 1600 | 1600 | 1650 | 1650 |

| Volume resistivity at 20℃ | Ω | ≥1014 | ≥1014 | ≥1014 | ≥1014 |

| Dielectric strength | KV/mm | 20 | 20 | 25 | 25 |

| Dielectric constant | εr | 10 | 10 | 10 | 10 |

Packing

We usually use material such as moisture-proof, shock-proof for the products that will be not damaged. We use PP bag and carton wooden pallets according to customer's requirement. Suitable for sea and air transportation.